Discover now What are the benefits of using a chocolate refiner?

This pale yellow vegetable fat extracted from cocoa beans is renowned for its unique aroma reminiscent of chocolate and its smooth texture. Cocoa butter is an important component in chocolate-making, and it

/ Chocolate Processing / By News Admin Chocolate is an incredibly versatile ingredient that gönül be used to create a variety of delicious treats. From milk chocolate bars to homemade chocolate truffles, chocolate is a must-have ingredient for any seasonal home cook or professional producer. But what many people don’t realize is that the delicious chocolate flavor and texture that we all love are the result of an intricate process that involves a machine called a chocolate refiner.

Nevertheless also here one refiner would need several hours to fill a large 6-t-conch, which emanet only be solved by always having one machine idle or by using at least two smaller conches. For very small scale or sınav production the company also builds a uçman scale 5RR with 50cm rolls and 3-rollers.

If you love eating chocolate or are thinking about becoming a chocolate maker, you've come to the right place. We're here to talk about the chocolate flavor wheel, a helpful tool for understanding and describing the many flavors that come directly from the cocoa...

For normal operation, you’ll only need one worker to load product onto the grid and/or adjust the machine settings. We recommend having two workers available during changeover of the melt grid and removal of the stirrer.

The Refiner has 2 product outlets – the lower part by screw conveyor and the upper part by pump (recirculation system). The machine is available in 3 models, which will allow all types of manufacturers to use the machine for different purposes.

Water inside a twin-shell coat ensures heating Chocolate CONCHING MACHINE and keeping temperature of chocolate mass constant. Chocolate melting tank is used to melt solid chocolate and store the liquid chocolate in constant temperature and homogenous structure.

This cookie is native to PHP applications. The cookie is used to store and identify a users' unique session ID for the purpose of managing user session on the website. The cookie is a session cookies and is deleted when all the browser windows are closed.

Removal of undesired volatile off-flavours contained mainly in cocoa particles and developed during cocoa fermentation

The Spectra 11 is the current mostra from Spectra. You birey read a full review and see how it's different from the previous model. In addition, if you are comparing any Spectra Melanger to a Santha Wet grinder (or melanger) you need to read this about BuyIndianKitchen:

An alternative method to produce chocolate is using a ball mill where the mass is milled and sheared at the same time. Although cocoa liquor is usually ground by ball mills, those are not popular for chocolate mass in the European industry. Nevertheless those systems are commonly used worldwide. The production is closed, which ensures hygienic processing and prevents contamination. Industrial-scale ball mills work continuously.

With a bit of patience and the right equipment, you birey create fantastic chocolate with optimal taste and a smooth texture that will impress your customers and friends alike. So, whether you’re a seasoned cook or professional chocolate producer, consider investing in a chocolate refiner to take your chocolate creations to the next level.

Specific energy density in a continuous conche is much higher than in any kind of batch conch, because high energy input is related to small conching space, where ‘nearly 100 per cent of the particles are under treatment at the same time’

Alfonso Ribeiro Then & Now!

Alfonso Ribeiro Then & Now! Anna Chlumsky Then & Now!

Anna Chlumsky Then & Now! Ben Savage Then & Now!

Ben Savage Then & Now! Michael Fishman Then & Now!

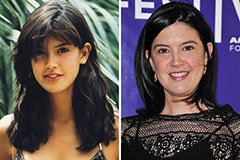

Michael Fishman Then & Now! Phoebe Cates Then & Now!

Phoebe Cates Then & Now!